Views: 0 Author: Site Editor Publish Time: 2025-09-10 Origin: Site

When you pick a capillary tube for a corrosive place, think about safety, strength, and how well it works. Special materials like stainless steel, nickel alloys, and titanium help stop corrosion. Stainless steel makes a shield with chromium. Nickel alloys fight acids. Titanium does not get damaged by seawater. These things help the tube stay strong and keep your system safe in tough places. Huashang Steel uses careful engineering to make capillary tubes for hard jobs.

Pick materials such as stainless steel, nickel alloys, or titanium for capillary tubes. These materials fight corrosion and help keep your system safe in tough places.

Always look at the diameter and wall thickness of the tubes. Tubes with thick walls are stronger. Tubes with thin walls help control flow better.

Make sure the capillary tubes follow rules like ASTM and ISO. This helps keep things safe and reliable in hard conditions.

Think about getting capillary tubes in custom lengths and sizes. Custom tubes fit your needs and make your system work better.

Regular checks and care are important. Look for rust or damage to help your capillary tubes last longer and keep your system working well.

When you pick capillary tubes for corrosive places, focus on corrosion resistance. Many things can hurt tubes in chemical plants. The table below shows common types:

Corrosion Mechanism | Description |

|---|---|

Crevice Corrosion | Happens in tight spaces. Needs oxygen. Makes pits and eats metal. |

Condensate Grooving | Grooves form from strong draining. This makes corrosion cells. |

Pitting Corrosion | Starts with small changes in metal. Even a few pits can cause big problems. |

Stress Corrosion | Attacks stressed spots. Makes tiny cracks along stress lines. |

Dezincification | Hurts copper-zinc alloys. Zinc leaves and makes the surface full of holes. |

Galvanic Corrosion | Happens when different metals touch in liquid. The weaker metal rusts faster. |

Pick materials that fight these problems. Inconel 625 and duplex stainless steel UNS S31260 are very good at stopping pitting and crevice corrosion. These work well in chemical and sea places. Huashang Steel uses smart methods to make capillary tubes that resist corrosion. Their tubes have smooth surfaces and exact sizes. This helps stop corrosion and makes them last longer.

You need to match the capillary tube to your job. Think about quality, corrosion resistance, strength, and surface finish. These things help the tube last and work well. Here are some tips:

Pick tubes with strong strength for hard jobs.

Choose smooth surfaces to lower corrosion and keep flow steady.

Make sure the material fits your chemicals. For very toxic chemicals, SUS 316L capillary tubes with 12% nickel resist corrosion better. For normal corrosive jobs, TP 316L with 10% nickel is good.

Huashang Steel gives custom lengths and very thin wall tubes. You can ask for tubes that fit your needs. Their careful engineering makes sure each tube meets tough rules for performance and strength.

Check if the capillary tubes meet important standards. ASTM and ISO standards help you know the tubes are safe and strong. These rules guide corrosion tests and make sure tubes can handle tough places. Look for these things:

ASTM standards tell how to prepare and test tubes for corrosion.

ISO standards show ways to check corrosion resistance.

Following these rules lowers the chance of problems in your system.

Huashang Steel follows these standards when making tubes. Their capillary tubes meet strict rules for safety and quality. You can trust their tubes in chemical, energy, and food jobs.

Tip: Always ask for papers and certificates when you buy capillary tubes. This helps you track the material and makes sure you get good products.

It is important to look at diameter and wall thickness. These things matter when you pick a capillary tube for corrosive places. Ultra-fine and ultra-thin tubes, like ones from Huashang Steel, help you control flow and pressure very well. Thin walls let you measure things carefully. Thick walls make tubes stronger and help them handle more pressure. You need to find the right mix for your job.

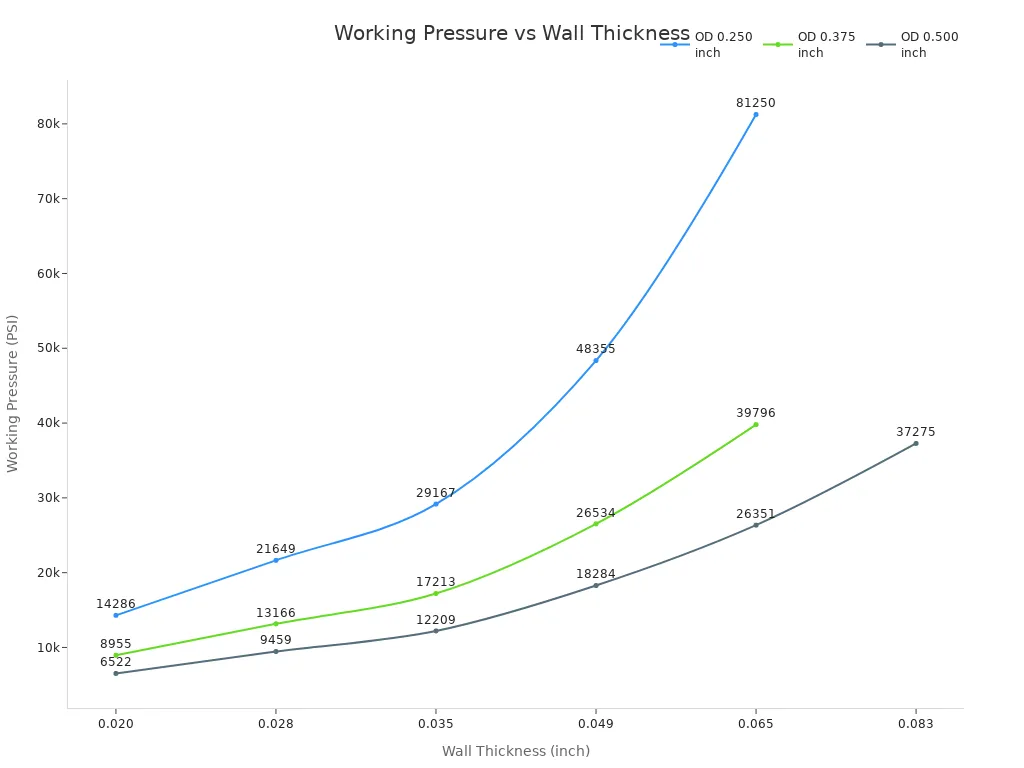

Here is a table that shows how wall thickness changes pressure ratings for different tube sizes:

OD (INCH) | WALL THICKNESS (INCH) | THEORETICAL BURST PRESSURE (PSI) | WORKING PRESSURE (PSI) | COLLAPSE PRESSURE (PSI) |

|---|---|---|---|---|

0.250 | 0.020 | 75,000 | 14,286 | 4,416 |

0.250 | 0.028 | 75,000 | 21,649 | 5,967 |

0.250 | 0.035 | 75,000 | 29,167 | 7,224 |

0.250 | 0.049 | 75,000 | 48,355 | 9,455 |

0.250 | 0.065 | 75,000 | 81,250 | 11,544 |

Tip: If you use thicker walls, you get more strength and higher working pressure. Thin walls are better for careful flow control.

Pick a tube length that fits your system. Huashang Steel can make custom lengths for you. Long tubes are good for sensors far away or special tools. Short tubes work in small spaces. Custom tubes help you use less material and make your system work better. You can ask for ultra-thin wall tubes or special sizes for your job.

Pick the best length for your setup.

Ask for custom sizes if you need special tubes.

Custom tubes help your system work safely and well.

Pressure and flow are very important in corrosive places. You need to check pressure ratings to make sure your tubes can do the job. Stainless steel tubes from Huashang Steel can handle high pressure and keep flow steady. The chart below shows how working pressure changes with tube size and wall thickness:

You should match the pressure rating to your system. High pressure ratings mean your tubes are safer and last longer. Steady flow helps your tools work right and gives good results.

Note: Always check the tube material and pressure ratings before you put capillary tubes in corrosive places. This helps you stop leaks and damage.

Stainless steel capillary tubes are used where corrosion is a problem. Stainless steel protects against many chemicals. Grades like 304 and 316 work in different places. Grade 316 is better near the coast and in food factories. It resists corrosion more than 304. Duplex and super duplex steel are stronger and last longer.

Here is a table that shows the benefits of common stainless grades:

Grade | Advantages |

|---|---|

304 | Used in many ways, good at stopping corrosion |

316 | Stops corrosion even better, good for coast and food jobs |

Huashang Steel sells capillary tubes in these grades. You can use them in chemical plants, energy systems, and food factories. Stainless steel capillary tubes help keep your system safe and last a long time.

Nickel alloys and titanium capillary tubes protect even more in tough places. Nickel alloys work in chemical plants and gas turbines. They stay strong when it is hot and resist acid corrosion. Titanium is great in seawater and on ships. Titanium Grade 2 is used on oil rigs and in fire systems. It works up to 180°F and helps save money on repairs.

Titanium alloys resist corrosion in seawater very well.

The U.S. Navy uses titanium for tanks, pipes, and hatches.

Nickel-titanium alloys stop many types of corrosion but can still crack and pit in seawater.

Huashang Steel makes capillary tubes from these materials for hard jobs.

You should compare materials before picking a capillary tube. Stainless steel resists corrosion and is strong. Nickel alloys are even stronger and work in tough places. Titanium resists corrosion best and stays strong when it is hot.

Here is a table to help you see the differences:

Material | Corrosion Resistance | Mechanical Properties |

|---|---|---|

Stainless Steel | Good, but can pit and crack in chlorides | Grades like 304 and 316 work well in tough places |

Nickel Alloys | Great, especially in hard conditions | Very strong when hot; used in chemical plants |

Titanium | Best, much better than stainless steel in tough places | Stays strong when hot; good for airplanes |

Huashang Steel gives you many choices for capillary tubes. You can pick the right material for your job and get the strength you need.

You have to check if your capillary tube follows industry standards. These rules help you trust the tube in tough places. ASTM and ISO are groups that make these rules. They test tubes for heat, cold, and quick changes. Tubes also get tested for drops, shaking, and oil. Here is a table with some test environments:

Testing Environment | Description |

|---|---|

High Temperature | Up to 150 °F |

Low Temperature | Down to 20 °F |

Humidity | Above 80% |

Rapid Temperature Change | Sudden shifts in temperature |

Bench Shock/Drop Test | Simulated impact testing |

Transportation Vibration and Shock | Testing during transport |

Oil Contamination | Exposure to oil |

Long-term Storage | Up to 3 years |

These tests make sure the tube stays safe and strong. Huashang Steel uses these rules to make good tubes.

You need to see if the tube’s material matches the chemical. If you pick the wrong one, the tube can break fast. Industry rules use ratings to show how well a material works with a chemical. Here is a simple chart:

Rating | Description |

|---|---|

A | Excellent - The material is inert with negligible effect on properties. |

B | Good - Slight chemical attack with minor effects. |

C | Fair - Partial attack, shortened life expectancy. |

D | Poor - Immediate damage, unsuitable for use. |

N/A | Unknown - Requires extensive testing. |

Always choose a tube with an “A” or “B” rating. Huashang Steel can help you pick the right tube for your job.

You should ask for papers and certificates when you buy tubes. These papers show where the tube came from and how it was made. Traceability helps you follow each tube from the factory to your site. This makes it easier to fix problems and follow safety rules. Huashang Steel gives full traceability for every capillary tube, so you can trust your choice.

Capillary tubes need to be flexible for easy setup. Flexible tubes bend around corners and fit small spaces. This helps you install systems fast and stops kinks. Kinks can block the flow inside the tube. Flexible tubes also handle stress better. You can use them in medical tools and chemical jobs. The tube can move or twist without breaking. Huashang Steel makes tubes with smooth, shiny surfaces and no seams. These things make the tubes strong and flexible. You get good performance in tough places.

Flexible tubes fit tricky spaces.

They stop kinks and keep flow smooth.

You can put them in and clean them easily.

Good capillary tubes must work in very hot or cold places. You want tubes that stay strong and do not rust when the temperature changes. PTFE and stainless steel are good choices for this. The table below shows how much heat each material can take:

Material | Temperature Range (°C) |

|---|---|

PTFE | -100 to +260 |

Tubes that resist heat keep your system safe. They do not melt or break when it gets hot. This is important for chemical jobs and other work with changing temperatures.

Durable capillary tubes last a long time and do not break easily. Tubes with no seams are stronger because they have no weak spots. A smooth surface keeps dirt away and stops rust. Stainless steel alloys from Huashang Steel resist many harsh chemicals. You get tubes that stay strong and work well, even with chemicals or stress. Durable tubes save money because you do not need new ones often.

Tip: Pick capillary tubes with no seams and smooth surfaces for better strength and rust protection.

You must pick the right capillary tube for your chemicals. First, find out which chemicals will touch the tube. Some chemicals hurt tubes fast. Others take more time to cause damage. Stainless steel is good for many uses. But you might need nickel or titanium alloys for strong acids or seawater. Always choose a tube that can handle the chemicals in your system. Huashang Steel has many grades. You can pick the best one for tough jobs.

Tip: Write down all chemicals you use. Use your list to choose the right tube material.

You need strong connections so your system stays safe. Here are some good tips:

Use compression fittings for tight seals with strong fluids. These fittings do not rust and you can use them again.

Do not use aluminum fittings with water fluids. They rust fast. Stainless steel fittings are best for most tough jobs.

Put PTFE tape on threaded fittings to stop leaks. Leave the first thread open to keep dirt out.

Pick good materials like carbon steel or stainless steel for connectors. Make sure the fitting matches the tube and the place.

These steps help your system stay safe and work well.

Taking care of your tubes helps them last longer. Follow these steps:

Maintenance Protocols | Description |

|---|---|

Protective Coatings | Put coatings like epoxy on tubes to block harmful stuff. |

Environment Management | Keep air and gases under control with good airflow and steady conditions. |

Proper Installation and Handling | Put tubes in carefully so they do not get bent. Use connectors that match the tube material. |

Regular Inspection and Maintenance | Look at tubes often for rust or damage. Fix problems fast. |

You keep your system safe and save money when you do these things. Huashang Steel makes tubes easy to check and built to last.

You can choose capillary tubes better in tough places if you follow some tips. Pick the right size and thickness so your system works well and does not leak. Use stainless steel or special alloys to stop corrosion. Make sure the tubes are flexible and strong. Check if they meet important rules.

A checklist helps you remember what can cause corrosion and what to do. Ask Huashang Steel or experts for help. Their tubes are strong, resist corrosion, and work well in hard places.

Benefit/Functionality | Description |

|---|---|

Incorporation of Corrosion Considerations | Checklists show what causes corrosion so you can plan better. |

Awareness of Requirements | They help you remember what is needed and what works best. |

Access to Expertise | You get advice from people who know how to stop corrosion. |