Views: 0 Author: Site Editor Publish Time: 2026-01-01 Origin: Site

Hexagonal steel tubing features a six-sided shape that stands out from round or square tubes. You benefit from its greater structural integrity and unique visual appeal. This geometry supports snug fits and strong structural support in various engineering projects.

In 2022, the market reached $14.8 billion and is growing fast.

The Asia-Pacific region leads with over half the market share.

You often find hexagonal steel tubing in applications where strength, fit, and appearance matter most.

Hexagonal steel tubing offers superior structural integrity, making it ideal for projects requiring strength and stability.

The unique six-sided shape enhances torque resistance, making it suitable for high-torque applications like offroad vehicles and machinery.

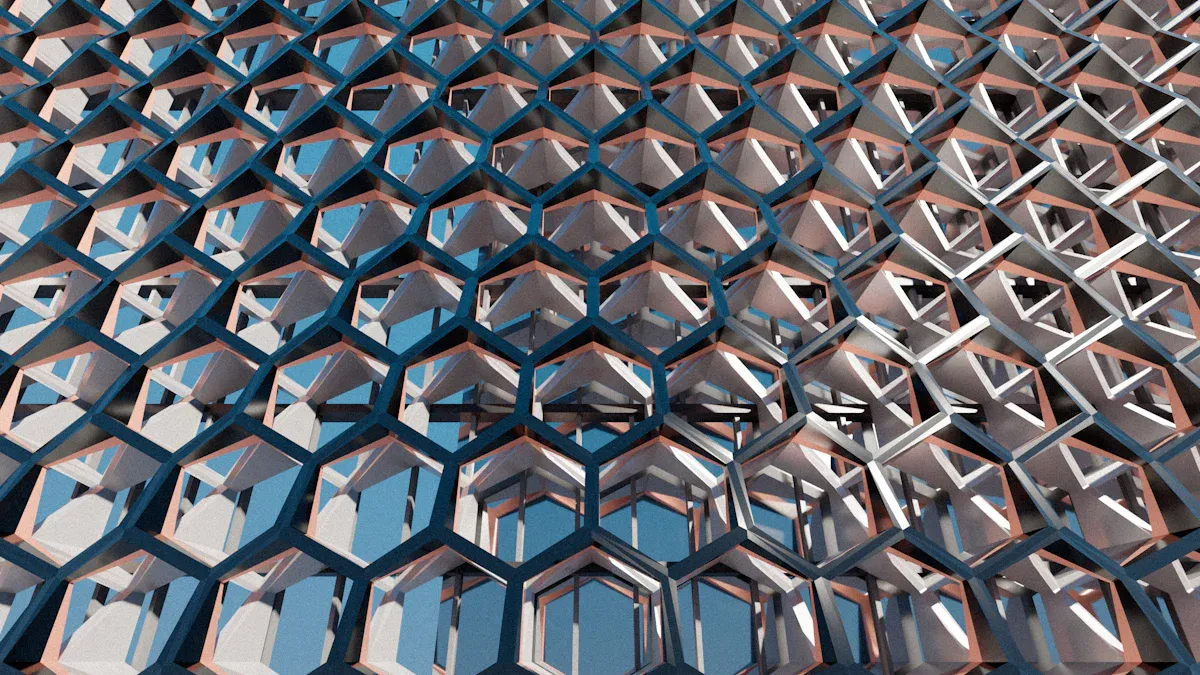

Aesthetic appeal is a key benefit; hexagonal tubing adds a modern touch to architectural and decorative projects.

Choosing the right surface finish is crucial; it affects durability and corrosion resistance, so match it to your project's needs.

Hexagonal tubing is versatile, used in various industries, including manufacturing, energy, and construction, due to its strength and efficiency.

You get strong support when you choose precision hexagonal steel tubing for your project. The six-sided shape helps spread force across the tube, making it stable and tough. This design gives you better strength and weight efficiency than round or square tubes. You can see how the key features work together in the table below:

Key Feature | Description |

|---|---|

High structural integrity | The hexagonal shape distributes stress evenly, improving strength and rigidity. |

Excellent machinability | Easy to cut, weld, and form into custom components. |

Superior strength-to-weight ratio | Provides a balance of strength and lightweight design. |

Versatile applications | Suitable for industrial, architectural, and decorative uses. |

You may face some challenges during fabrication. These include welding issues, complex customization, tooling limits, and strict quality control. You need to check for cracks or flaws to keep the tubing strong.

Tip: Manufacturers use strict tolerances and advanced measurement tools like calipers and laser scanners to make sure each tube fits perfectly.

You need tubing that can handle twisting and turning forces. Seamless hexagonal steel tubing stands out because it resists torque better than many other shapes. The six-sided design keeps the tube stable when you use it in high-torque or heavy-duty jobs. This makes it a top choice for parts that rotate or move under pressure.

The hexagonal shape helps the tubing withstand twisting forces.

You get mechanical stability for moving parts.

The tubing works well in offroad vehicles, machinery, and material handling systems.

You should know that production costs and equipment quality can affect the price of hexagonal steel tubing. Raw materials, market demand, and competition also play a role.

You want your project to look good and work well. High strength Hexagonal steel tubing gives you both. The unique shape adds a modern touch to buildings, furniture, and art pieces. You see this tubing in places where design matters as much as strength.

The six-sided look stands out in architectural projects.

Designers use it for creative and decorative purposes.

You get a blend of style and function.

You can choose from different surface finishes to match your design needs. Regular inspections and strict quality checks help keep the tubing looking sharp and performing well.

You often choose carbon steel for hexagonal steel tubing because it offers strength and affordability. Carbon steel comes in several grades, each with its own uses. You see low-carbon grades in light-duty projects, while medium and high-carbon grades work well for heavy-duty tasks. You can rely on industry standards to guide your selection. The ASTM specifications cover many grades of carbon and alloy steel seamless mechanical tubing. If you need to weld the tubing, you must follow procedures that match the grade and service.

Standard | Description |

|---|---|

ASTM Specifications | Covers several grades of carbon and alloy steel seamless mechanical tubing. When welding is used for joining, the procedure must be suitable for the grade and intended service. |

You may need alloy steel when your project demands extra strength or heat resistance. Alloy steel contains elements like chromium, nickel, or molybdenum. These elements boost the tubing’s performance in tough environments. You can compare alloy steel and carbon steel using the table below:

Property | Alloy Steel | Carbon Steel |

|---|---|---|

Thermal Conductivity | Generally less conductive than carbon steels | Higher thermal conductivity (about 45 W/(mK)) |

Tensile Strength | Higher tensile strength (up to 960 MPa) | Lower tensile strength (450 MPa) |

Applications | Used in high-temperature applications | Used in applications without high temperatures |

You use alloy steel hexagonal steel tubing in places where you need to handle high temperatures or heavy loads.

You can pick from many surface finishes to match your project’s needs. Each finish affects corrosion resistance, durability, and appearance. Here are some common types:

Surface Finish Type | Description |

|---|---|

Seamless | No seams, providing a smooth finish. |

Welded | Tubes made by welding steel sheets. |

Brushed | Textured finish for aesthetic appeal. |

Pickled | Removes surface impurities. |

Solution Annealed | Enhances corrosion resistance. |

Polished Grit 120 – 600 | Varying levels of polish for shine. |

Mirror Polished | High gloss finish for aesthetics. |

No.1 – Matte finish

2B – Standard finish

#400 Bright – Semi-bright finish

#600 Bright – Bright finish

6K Mirror – High gloss finish

8K Mirror – Ultra high gloss finish

Hair Line – Textured finish

Tip: You should select a finish that matches your environment and design goals. A polished or mirror finish gives you a sleek look, while pickled or solution annealed finishes help resist corrosion.

You see hexagonal steel tubing used in offroad vehicles for strong frames and roll cages. The six-sided shape helps parts resist twisting and bending when you drive over rough ground. You get better safety and durability. Many engineers choose this tubing for custom suspension systems and steering components. You can trust it to handle heavy loads and sudden impacts.

Tip: Hexagonal steel tubing gives you a snug fit for joints and connectors, making assembly easier and more secure.

You use hexagonal steel tubing in material handling systems to move goods safely and efficiently. The unique shape improves how structures carry weight and absorb energy. You get stable loading and less force fluctuation during impacts. The table below shows how this tubing helps your system work better:

Benefit | Description |

|---|---|

Structural Efficiency | Hexagonal design optimizes space, enhancing overall performance in material handling systems. |

Energy Absorption | Thin-walled tubes dissipate energy through specific deformation mechanisms, improving crashworthiness. |

Stability | Certain lattice designs offer stable loading behavior, minimizing force fluctuations during impact. |

You can rely on these features to keep your warehouse or factory running smoothly.

You find hexagonal steel tubing in the production of nuts and bolts. The six-sided shape matches the design of these fasteners. You get precise cuts and strong threads. Manufacturers use this tubing to make parts that fit tools and machines perfectly. You can count on the tubing to provide the right grip and torque for assembly.

You use hexagonal steel tubing in many industries outside of automotive and construction. In manufacturing, you build custom machinery and support structures. In the energy sector, you see it used for solar panel mounts and supports. The list below shows some common uses:

Manufacturing: Custom machinery components and support structures

Energy: Solar panel mounts and infrastructure

You should know that hexagonal steel tubing uses standard amounts of material. Other shapes, like triangular or non-hexagonal tubes, use less material and have a lower environmental impact. The table below compares the environmental effects:

Tubing Shape | Material Efficiency | Environmental Impact |

|---|---|---|

Hexagonal | Standard | Higher material extraction |

Triangular | 15% less material | Reduced eco impacts |

Non-hexagonal | 20% less material | Lower environmental footprint |

You need to balance strength, fit, and environmental concerns when you choose tubing for your project.

When you compare hexagonal steel tubing to round tubing, you notice several key differences. The shape of each tube affects how it handles stress and where you might use it.

Hexagonal tubing can show higher stress at the corners. This can impact how strong the tube is in certain spots.

Hollow hexagonal tubes often perform better than solid tubes when you look at the weight.

Solid round tubes are usually stronger if you use the same diameter. However, the hexagonal design can give you better results in some special uses.

You might pick hexagonal tubing if you want a snug fit or need to resist twisting. Round tubing works well for fluid flow and pressure systems.

You may find hexagonal tubing easier to work with than square tubing. The flat sides of hexagonal tubes help you weld and assemble parts quickly.

The flat surfaces make welding and assembly simpler than with square tubing.

The unique hex shape reduces stress points. This gives you more strength and stability during assembly.

You can use hexagonal tubing when you want both easy assembly and strong joints. Square tubing works well for basic frames, but hexagonal tubing gives you more options for custom designs.

Hexagonal steel tubing stands out because of its strength and stability. You get better load distribution, which means the tube can handle heavy-duty jobs with less wear. This design often leads to lower maintenance needs compared to other shapes. You save time and money because you do not have to repair or replace the tubing as often. In high-stress settings, hexagonal tubing keeps your projects running smoothly and safely.

Tip: Choose hexagonal tubing for projects that need both durability and easy upkeep. You will notice the difference in performance and reliability.

You gain strong support, reliable performance, and flexible design when you choose hexagonal steel tubing. Many engineers and manufacturers prefer this shape for its added strength, corrosion resistance, and efficient handling. You see it used in construction, manufacturing, and agriculture. Industry leaders praise its quality and custom options:

Industry Professional | Feedback |

|---|---|

President, grain spouting supplier | "The quality of the steel tubing is always excellent, and their delivery timelines are always reliable." |

Production Planner/Buyer, carwash systems | "Custom cut lengths have been a game-changer for our operations." |

You can trust hexagonal steel tubing to meet your project needs and support new innovations in engineering.

You get better strength because the six-sided design spreads force evenly. This shape helps prevent bending and twisting.

You can weld hexagonal steel tubing with standard equipment. The flat sides make welding simpler than round tubes.

Use proper welding techniques for the steel grade.

Inspect welds for cracks.

You see hexagonal steel tubing in offroad vehicles, material handling systems, and nuts and bolts manufacturing.

Application | Benefit |

|---|---|

Offroad vehicles | Strong frames |

Material handling | Stable structures |

Fastener production | Precise shapes |

You pick a finish based on your project’s needs.

Note: Polished finishes look sleek. Pickled or annealed finishes resist corrosion. Always match the finish to your environment.