Views: 0 Author: Site Editor Publish Time: 2025-09-12 Origin: Site

You will see that many modern industries pick capillary tube solutions. They do this because these tubes are very precise and work well. Capillary tubing has exact sizes and smooth surfaces. This helps things work better in important jobs. Many fields need special tubing. Look at the table below. It shows how aerospace, medical, and chemical industries use advanced tubing:

Sector | Description |

|---|---|

Aerospace | Flexible, flame-retardant, and low-temperature resistant PVC tubing designed for aircraft systems. |

Medical | High-quality heat shrink solutions for medical applications, ensuring optimal protection performance. |

Chemical | Seamless stainless steel and nickel alloy tubing used in chemical processing and defense sectors. |

You can get good results from capillary solutions made by Huashang Steel. This is true when you need strong Tube products for tough places.

Capillary tubes give very exact flow control. This makes them great for jobs that need high accuracy, like medical tests and chromatography. Stainless steel capillary tubing is strong and does not rust. This makes it good for tough places and for using a long time. Capillary tubes can bend and fit into small spaces. This helps make installing them in tricky systems easier. Picking the right tubing can lower repair costs. It can also help the system work better, especially in hard jobs. Capillary tubes need less care than traditional tubing. This saves time and supplies when doing maintenance.

Capillary tubes and traditional tubing are not the same. Capillary tubes have much smaller diameters than traditional tubing. You often find capillary tubes in hplc and uplc systems. These systems need very precise flow control. Traditional tubing is bigger and works for jobs that do not need tight tolerances. Capillary tubes help you get accurate results in ultra-performance liquid chromatography.

Here is a table that shows how capillary tubes and traditional tubing are different in size, tolerances, and surface finish:

Property | Capillary Tubing | Traditional Tubing |

|---|---|---|

Diameter Range | Less than 1/8 inch (often less than 1/16 inch) | 1/8 inch to several inches |

Dimensional Tolerances | Tight tolerances, important for precision jobs | Less strict tolerances |

Surface Finish | Very smooth surface from special processes | Usually lower surface quality |

Capillary tubes have special features. They have tight dimensional tolerances. Their surface finish is very smooth. You can see these features in products like the Precision Capillary Seamless Tube from Huashang Steel. Capillary tubes use advanced manufacturing methods. Additive manufacturing helps make complex shapes. Better surface finishing makes the flow inside the tube smoother. Special alloys make the tubes strong against corrosion and heat.

Here is a table showing some new improvements in capillary tube technology:

Advancement Type | Description |

|---|---|

Additive Manufacturing | Lets you make complex capillary shapes. |

Improved Surface Finishing Techniques | Makes flow inside capillary tubes better. |

Specialized Alloys | Gives better resistance to corrosion and heat for tough jobs. |

You should think about the good and bad sides before you pick capillary or traditional tubing. Capillary tubes protect instruments from temperature changes. They make things safer because you can reach them easily. If you use longer capillary tubes, you might get slower response times and less accuracy. Traditional tubing does not have these problems, but it is not as precise as capillary tubes.

Here is a table that lists the main pros and cons:

Advantages | Disadvantages |

|---|---|

Protects instruments from temperature changes | Longer capillary tubes can lower accuracy |

Better safety because of easy access | Longer tubes can slow down response time |

Capillary tubes are best for jobs that need precision and safety. Traditional tubing is better for regular uses.

Many modern industries need to control flow very carefully. Capillary tubes help with this job. Their small size and smooth inside let you move fluids or gases exactly. In hplc and uplc systems, the flow must stay steady and exact. Capillary tubes from Huashang Steel help keep this control. You can use them in devices that need high precision. Even a tiny change in flow can change the results.

Capillary tubes work well in very tough conditions. They can handle temperatures from -300 °F up to 750 °F. Some special designs, like the Ashcroft® MicroTube™ siphon, work with pressures up to 5,000 psi and temperatures up to 800 °F. Finned siphons can handle up to 3,000 psi and 700 °F. This means you can trust capillary tubes in hard places.

Tip: If you need to measure or control flow in places with high pressure or heat, capillary tubes work well and are reliable.

You want your work to be very exact. Capillary tubes help because they are made with great accuracy. The Precision Capillary Seamless Tube from Huashang Steel is a good example. It keeps the inside, outside, and wall thickness very close to the right size. This helps you get the same and correct results every time.

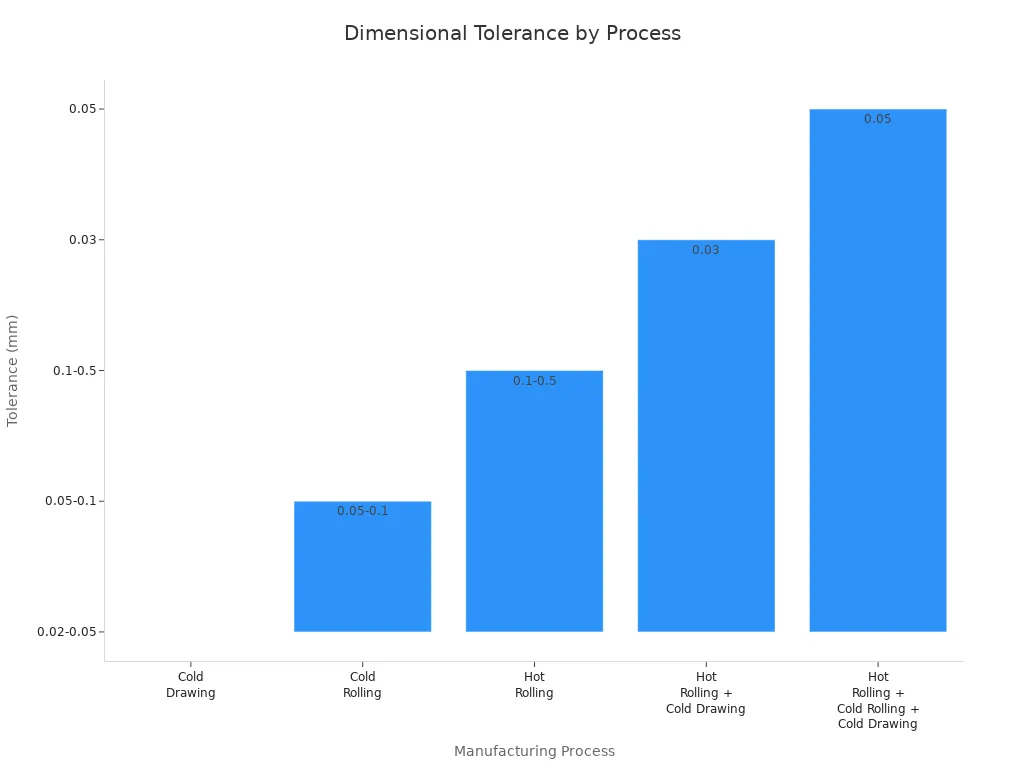

Here is a table that shows the usual size limits for different ways of making tubes:

Manufacturing Process | Dimensional Tolerance |

|---|---|

Cold Drawing | ±0.02-0.05mm |

Cold Rolling | ±0.05-0.1mm |

Hot Rolling | ±0.1-0.5mm |

Hot Rolling + Cold Drawing | ≤±0.03mm |

Cold Rolling + Bright Annealing | N/A |

Hot Rolling + Cold Rolling + Cold Drawing | ≤±0.05mm |

You should also think about how smooth the inside is. Capillary tubes with polished insides can be as smooth as Ra 6.4 nm. This smoothness is important in medical and science work. It keeps samples clean and helps you get correct test results. You can clean these tubes easily, which is important for places like medicine factories.

Stainless steel capillary tubes control fluids and gases very well in medical tools and science equipment.

They do not rust, so you can use them with strong chemicals.

Their smooth surfaces make them easy to clean for safe use in sensitive places.

In jobs that need high precision, you also look at the length-diameter ratio. A higher ratio means you can measure more accurately. For example, some flow meters use capillary tubes with a length-diameter ratio from 10,000 to 20,000. Some tubes go even higher than 20,000. This helps you get steady and correct flow readings.

You can see that capillary tubes give you the performance you need for hard jobs. Their tight size limits, smooth insides, and ability to handle high pressure and heat make them the best for high precision devices.

Sometimes you need tubing for hard jobs. Stainless steel capillary tubing has many good points. It does not rust easily, so it lasts longer in rough places. You can use these tubes with acids and strong chemicals. Stainless steel capillary tubes stay strong even when it gets hot. They do not crack or burst when under pressure. If you work where it is wet or there are strong chemicals, these tubes keep working well.

Huashang Steel makes seamless capillary tube products. You can pick long stainless steel coil tubing for big projects. Seamless tubes have smooth insides, which help with cleaning and precision. Small tubes fit into tight spaces. You get tubes that work well and last a long time.

Here are the main benefits of stainless steel capillary tubing:

High corrosion resistance for durability

Withstands high temperatures and mechanical stress

Works well with acids, alkalis, and other corrosive substances

Maintains strength in humid and aggressive conditions

Handles high pressure without cracking

Sometimes you need tubes made from other materials. Duplex steel and nickel-based alloys have special strengths. Huashang Steel also makes seamless tubes from these alloys. Duplex steel is stronger and resists rust better than regular stainless steel. Nickel-based alloys are best for very tough places, like oil plants or ships.

The table below shows how these materials compare:

Property | Stainless Steel | Nickel Alloys |

|---|---|---|

Corrosion Resistance | Good, but inferior to nickel alloys | Superior, especially in extreme environments |

Temperature Resistance | Reduced mechanical properties at high temperatures | Excellent, stable at higher temperatures |

Cost | More cost-effective for standard applications | Higher due to special composition and manufacturing costs |

Common Applications | Food processing, pharmaceuticals, automotive | Petrochemical, aerospace, marine engineering |

You should choose the right tube for your job. Stainless steel capillary tubing works for most jobs. For very hard jobs, duplex steel or nickel-based alloys may be better. Always pick seamless tubes and high quality for the best results.

You want to know how much you pay first. Capillary tubing costs more than traditional tubing. You pay extra for tight tolerances and smooth surfaces. Huashang Steel makes tubing that meets strict rules. You may spend more if you pick stainless steel or special alloys. The price changes with size, length, and material. If you need tubing for medical or aerospace jobs, costs are higher because these jobs need more precision.

Think about how much it costs to keep tubing working. Capillary tubing saves money over time. It does not rust and needs little cleaning. You spend less on repairs and replacements. Traditional tubing needs more care, especially in tough places. If you use tubing in chemical plants or energy projects, you want tubing that lasts. Stainless steel tubing from Huashang Steel helps you avoid many problems.

Tip: Picking the right tubing can lower your maintenance costs and keep your system working well.

You should also think about the effect on the environment. Some ways to make tubes, like Shaped-Tube Electrolytic Machining (STEM), hurt the environment more than Capillary Drilling (CD). STEM’s impact is 12 times bigger than CD for one hour of work. The biggest problem comes from the materials used, which can harm people’s health.

STEM uses more resources and makes more waste.

CD is safer for the environment and people.

You want your tubing to last a long time. Capillary tubing gives you good value because it stays strong. You spend less on repairs and replacements. Stainless steel tubing works well in hard places and keeps its shape. You get better safety and performance. If you pick high-quality tubing from Huashang Steel, you protect your equipment and save money over time. You also help the environment by choosing products that last longer and use safer ways to make them.

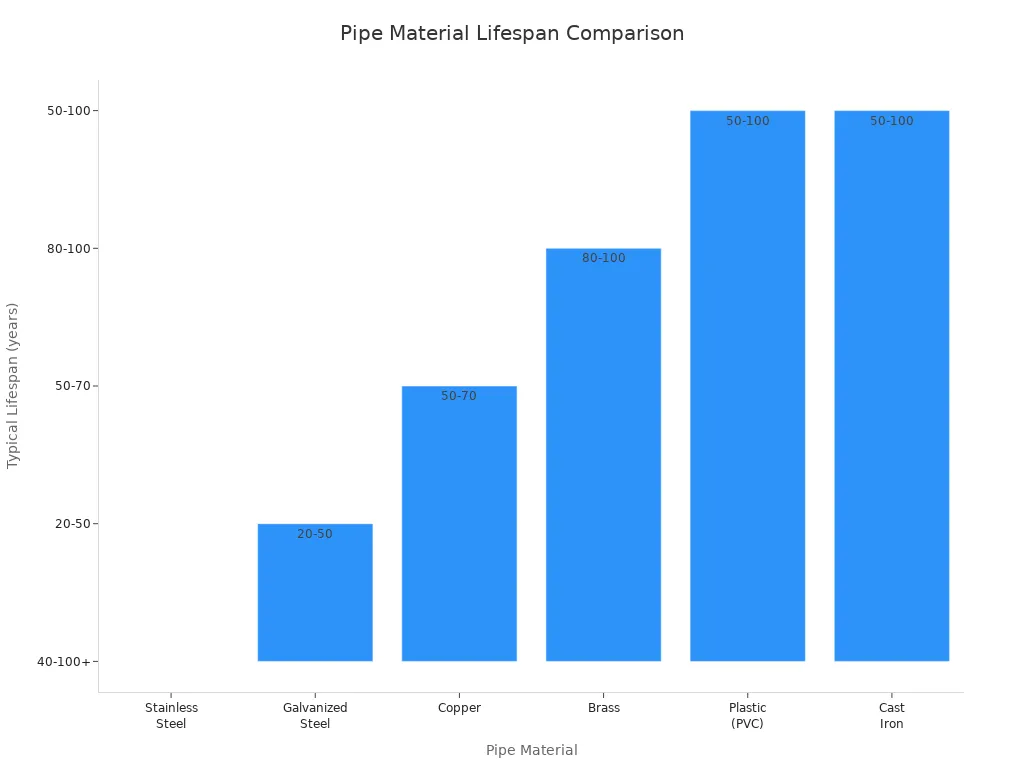

You want tubing that lasts a long time. Stainless steel capillary tubes from Huashang Steel last many years. These tubes do not rust or break easily. You can use them in tough places without worry. When you look at other materials, you see they do not last as long.

Pipe Material | Typical Lifespan | Advantages |

|---|---|---|

Stainless Steel | 40-100+ years | Corrosion-resistant, durable |

Galvanized Steel | 20-50 years | Cost-effective, but prone to rust |

Copper | 50-70 years | Long-lasting but can develop pinhole leaks |

Brass | 80-100 years | Durable, but may contain trace lead amounts |

Plastic (PVC) | 50-100 years | No corrosion, but sensitive to temperature |

Cast Iron | 50-100 years | Durable, but prone to rust over time |

Stainless steel capillary tubes can last more than 40 years. Some tubes work for over 100 years. You do not need to replace them often. This saves you money and keeps your system working.

You want tubing that is easy to take care of. Capillary tubes need less care than traditional tubing. Their simple shape means fewer things can break or leak. You can keep your system working with easy checks.

Look at your tubes every month to find leaks or loose parts.

Capillary tubes break less because they have fewer parts.

Change gaskets and filter driers every two years.

Traditional tubing needs more care because it has more parts.

Tip: Checking your tubes often helps you find small problems early. You spend less money and time fixing things when you use capillary tubes from Huashang Steel.

Capillary tubes work well and are easy to care for. They are a good choice for industries that want to spend less time on repairs and keep their equipment working longer.

Capillary tubes are used in many medical tools. They help collect and test blood very carefully. When doctors check blood, they want it to hurt less. Capillary blood draw lets you get blood without using a big needle. This is good for babies, kids, and adults who need blood tests often. Capillary tubes are used for hematocrit testing, glucose checks, and hemoglobin tests. These tubes work with tiny amounts of blood and keep things clean.

Here are the main ways capillary tubes are used in medicine:

Hematocrit testing checks how many red blood cells are in blood. You use a capillary tube to get a small blood sample.

Glucose monitoring helps people with diabetes check their sugar. You use a capillary tube to take a tiny drop of blood.

Capillary tubes are best for testing babies and kids. They make blood draws easier and less painful.

In labs, capillary tubes help test small blood samples. You get good results with just a little blood.

Point-of-care tests use capillary tubes in clinics and faraway places.

Capillary tubes are also used for microhematocrit centrifugation. This helps measure hematocrit with a small blood sample. You do not need a big needle, so it is easier for patients. Capillary tubes are used in hplc systems to move fluids exactly. These tubes keep samples clean and help get correct results.

Tip: Capillary blood draws are less painful and good for people who need many tests. They help patients feel better and give good blood sample results.

Capillary tubes are used in many industries. They help move fluids and gases very carefully. In aerospace, capillary stainless steel tubes are used in hydraulic systems. These tubes move hydraulic fluid to important parts like landing gear. The tubes must handle high pressure, heat, and shaking. Stainless steel capillary tubes from Huashang Steel are strong and last a long time.

In fuel systems, capillary tubes move fuel from tanks to engines. The tubes work in cold places and are light. This helps save fuel in planes and cars. In cars, capillary tubes are used in fuel injection systems. They control how much fuel goes to the engine and help the engine work better. Capillary tubes are also in air conditioners. They control how much refrigerant moves and keep things cool. Exhaust monitors use capillary tubes to check gases and follow rules.

Industry | Application | Purpose |

|---|---|---|

Aerospace | Hydraulic systems | Move hydraulic fluid for landing gear and other parts. |

Aerospace | Fuel delivery systems | Move fuel from tanks to engines, even when it is cold. |

Automotive | Fuel injection systems | Control fuel flow for better engine work and saving fuel. |

Automotive | Air conditioning units | Control refrigerant flow for good cooling. |

Automotive | Exhaust monitoring devices | Check exhaust gases to follow pollution rules. |

Capillary tubes are also used in chemical and energy jobs. In petrochemical plants and refineries, Incoloy capillary tubes are used for sampling and injection. These tubes do not get damaged by acids or other harsh chemicals. The tubes keep working in hard places. In nuclear power plants, capillary tubes help watch and control systems. They can handle radiation and heat, so they are good for important jobs. In hot gas systems, capillary tubes carry very hot gases. The tubes do not melt, even at 1000°C.

In petrochemical plants, capillary tubes move harsh fluids.

In nuclear power, capillary tubes help watch systems safely.

In energy projects, capillary tubes carry hot gases.

You pick capillary tubes from Huashang Steel for important jobs. These tubes give you the careful work and strength you need. You keep samples safe and your machines working well.

You want your tubing system to work well. Start by checking your equipment. Look at the design details like material, length, and size. Make sure the tubes fit your system’s needs. Put the capillary tube where there is no shaking or strong movement. This keeps your system safe. Connect flanges tightly. Clean the faces and use the right bolts and gaskets. Do not bend or stretch the tube too much. This helps the tube stay strong and stops leaks. Install the tube with the right slope. This keeps fluid moving and stops air bubbles. If you use capillary tubes in hplc systems, be extra careful. Small mistakes can change your results. You might have problems during installation. If you do not cut the tube right or remove sharp edges, you can hurt the seal and make the system dirty. If you do not push the tube in far enough, it can get loose or fall off. Tighten the fittings just enough. If they are too loose or too tight, you can get leaks.

Tip: Always check tubes for scratches or dents before you install them. Clean and get each tube ready so you do not have problems later.

You need tubing that fits your workspace. Capillary tubes from Huashang Steel bend and twist easily. You can put them in tight or odd spaces without trouble. Their strength lets them handle high pressure and pulling.

Property | Capillary Tubes | Traditional Tubing |

|---|---|---|

Flexibility | Bends and twists very well | Not very flexible |

Adaptability to Layouts | Fits in tricky places | Hard to use on uneven surfaces |

Resistance to Deformation | Stays strong during setup | Can bend out of shape |

You can shape capillary tubes to go around corners or through small spaces. This makes them great for busy factories or labs. Their strong build helps stop damage during setup. You spend less time worrying about leaks or breaks.

Note: Capillary tubes give you more ways to install them. You can trust them to stay strong and flexible, even in hard places.

Picking the right tubing depends on what you need. Capillary tubes are good for jobs that need high accuracy, like blood tests or chromatography. Stainless steel capillary tubing is best in tough places because it does not rust and can handle heat. When you choose, think about:

The environment and how much pressure there is

What you will use the tubing for, like medical or industrial jobs

If the tubing meets the rules for your industry

Remember, always pick tubing that fits your system. This helps keep things safe and working well.