Views: 0 Author: Site Editor Publish Time: 2025-09-15 Origin: Site

Application Field | Examples of Use |

|---|---|

Medical Treatment | Injection needle tube, puncture needle tube |

Industrial Sensors | Temperature sensor guide tube |

Aerospace | Optical cable support tube |

Huashang Steel uses smart methods like changing the process as they work and using lasers to shape the tubes. This helps them make sure every Capillary Tube is the right size and works the same way every time.

Capillary tubes help control fluids very accurately in many industries. They are used in medicine, aerospace, and sensors. Their special design lets them control flow very well.

Capillary tubes work the same way for a long time. They can handle changes in temperature and pressure. This makes them work reliably.

Capillary action lets fluids move through tiny tubes by themselves. No outside force is needed. This is very important in science and medicine.

Capillary tubes can be made in different sizes, lengths, and materials. This means they can fit special needs in each industry.

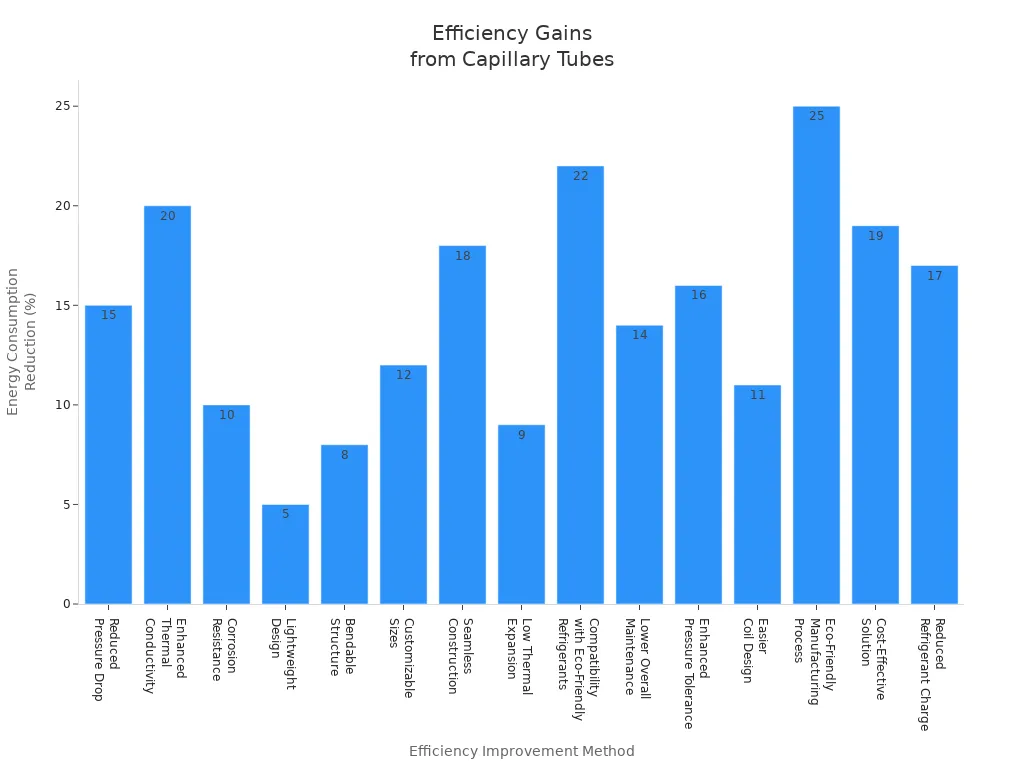

Using capillary tubes can make things work better and save energy. Their design lowers pressure loss and helps heat move faster.

A capillary tube helps control fluids in many systems. This small tube is important for flow regulation. The design of a capillary tube gives you some benefits:

The small inside part lets you control how much fluid goes through.

Careful manufacturing makes sure each capillary tube works the same way.

Stainless steel keeps the tube from rusting, so you can use it with many fluids.

The tube is strong and can handle pressure and stress.

It works well in very hot or cold places and keeps its shape.

You can clean and sterilize the tube easily, which is good for medical and food uses.

Huashang Steel uses special ways to make sure every capillary tube meets high standards. You get a tube that helps you measure and control fluids very well. This kind of flow control is needed in medicine, electronics, and energy.

A capillary tube gives steady performance for a long time. Some things help keep the flow even:

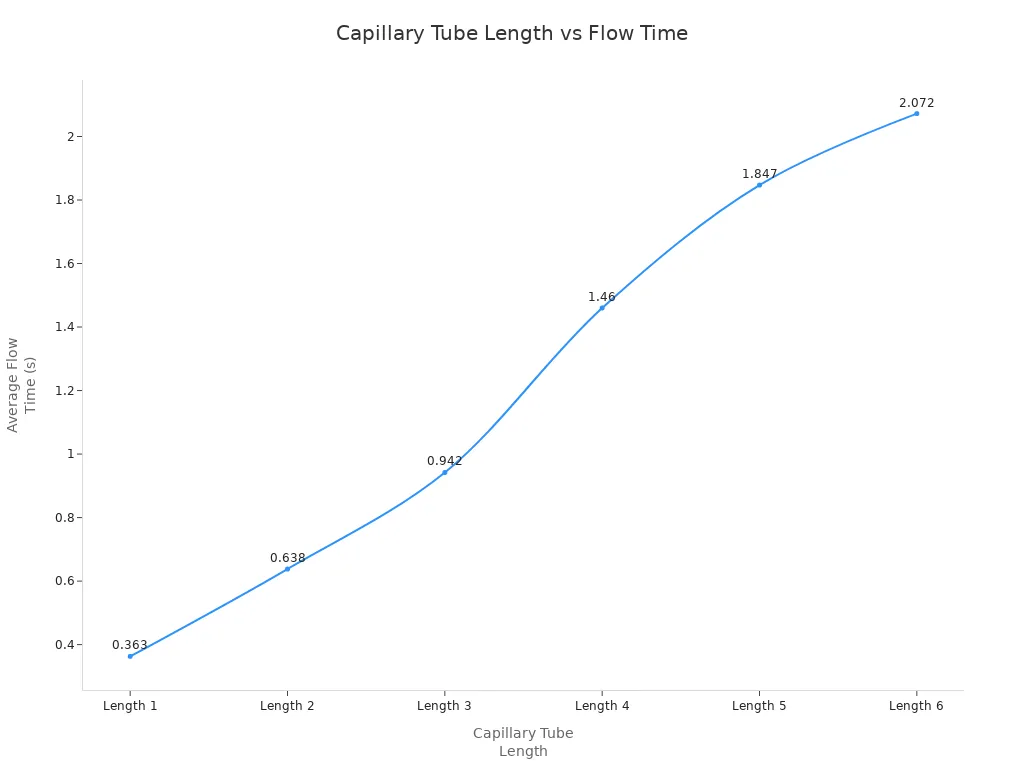

The length of the capillary tube changes how fast the fluid moves.

The amount of fluid that goes through stays steady.

The tube can adjust when heat changes, so the flow stays the same.

The capillary tube acts like a valve. It keeps the flow path the same size, even if pressure or temperature changes. This means you can trust the tube to work the same way, even in hard situations.

You can see how the length of a capillary tube changes flow time in the table below:

Capillary Tube Length (s) | Average Flow Time (s) |

|---|---|

Length 1 | 0.363 |

Length 2 | 0.638 |

Length 3 | 0.942 |

Length 4 | 1.460 |

Length 5 | 1.847 |

Length 6 | 2.072 |

This data shows that when you make the capillary tube longer, the average flow time gets longer too. You can use this to pick the right tube for your job. Huashang Steel makes capillary tubes that help your system work well, even when things get tough.

Capillary action lets fluids move up tiny tubes. Gravity tries to pull the fluid down, but special forces help it go up. These forces are stronger in very thin tubes, like the ones from Huashang Steel. You can see capillary action when water climbs a straw or ink spreads in paper. Here is what happens in capillary tubes:

Liquids move in small spaces without outside force.

Adhesion makes the liquid stick to the tube’s wall, and cohesion keeps the liquid together.

Smaller tubes let the liquid rise higher.

Capillary action matters most when the tube is very thin. That is why ultra-fine tubes work well in science and medicine.

A capillary tube controls fluid by making a pressure drop. One end has more pressure than the other end. This difference helps you control how fast the fluid moves. Many things change the pressure drop in a capillary tube:

The tube’s length and width

How fast the fluid moves

What kind of fluid is inside

If there are bends or valves

You can use math to find the pressure drop. The formula uses the tube’s length, width, and the fluid’s speed and thickness. A longer or thinner tube makes a bigger pressure drop. In real life, things like vapor speed and liquid plugs can also change the pressure drop.

You want to know how much fluid will go through the tube. Scientists use math models to guess the flow rate. These models look at things like temperature and pressure. They help you make systems that work the same way every time. In jobs like refrigeration, these guesses help you pick the right tube. Huashang Steel uses these ideas to make sure their capillary tubes work well and give steady results.

Capillary tubes are used in many jobs. Huashang Steel makes tubes for energy, food, chemicals, oil, gas, and boilers. These tubes help move fluids in hard places. The tubes must handle heat, rust, and pressure. The table shows how different jobs use capillary tubes and what they need:

Application Area | Performance Requirements |

|---|---|

Nuclear Power Plants | Tubes must work well with radiation and heat. They help watch and control systems. |

Petrochemical Setups and Refineries | Tubes must not rust. They are used for sampling and adding fluids. |

High-Temperature Gas Systems | Tubes must not bend or melt in very hot gas. |

Aerospace | Tubes must carry fuel and fluid with no leaks. They must work in tough places. |

Huashang Steel lets you pick the tube you need. You can choose the size, length, and what it is made of.

Capillary tubes are used in medical tools and sensors. They help move small amounts of fluid very carefully. Huashang Steel makes tubes for needles and temperature sensors. These tubes use capillary action to move fluids. The table below explains how this works:

Concept | Description |

|---|---|

Capillary Action | Fluid moves in the tube by capillary pressure. This is important for medical fluid control. |

Capillary Pressure | Pc=2γcosθR, where Pc is pressure, R is tube radius, γ is fluid surface tension, θ is contact angle. |

Fluid Behavior | Flow in small devices follows special rules. This helps control fluids well. |

People trust these tubes for safe and correct medical tests and sensor results.

Capillary tubes are used in electronics and aerospace. They help move fluids and gases very exactly. In aerospace, tubes carry fuel and fluids. They work in very hot or cold places and under high pressure. The tubes must not leak and must keep things safe. In electronics, tubes help make microchips. They control how chemicals and glue move. This helps make good parts and saves materials.

Tip: You can pick tubes made from stainless steel, nickel alloys, or titanium. Each one is good for different jobs:

Stainless steel does not rust and can take heat.

Nickel alloys are good for strong chemicals.

Titanium is strong in very hot or cold places, so it is good for planes and cars.

Huashang Steel gives you many choices, so you always get the right tube for your work.

It is important to control fluids very carefully in big systems. Huashang Steel capillary tubes help you do this well. These tubes are very thin and made with exact measurements. This helps you move fluids to the right spot. You see these tubes in medical tools, coolers, and lab machines. The bright annealing process makes each tube smooth and shiny. This keeps the inside clean and stops dirt from getting in. Clean tubes are needed for medicine and food.

Here is why capillary tubes are special:

Feature | Description |

|---|---|

Precise Volume Markings | You can measure blood samples correctly. |

Leak-Proof Seals | You keep samples safe and do not lose them. |

Broad Compatibility | You can use these tubes with lab tools. |

Ergonomic Design | You can hold the tubes easily and make less mistakes. |

User-Friendly Handling | You make patients feel better during tests. |

You can count on Huashang Steel tubes to work every time.

Capillary tubes from Huashang Steel help you save energy and time. The tubes have thin walls, so fluids move easily. This means less mixing and better heat movement. The tubes do not rust, so they last longer and need less fixing. The bright annealing process makes the tubes even cleaner and stronger for hard jobs.

Here are ways capillary tubes help you work better:

Lower pressure drop saves energy in coolers.

Better heat movement helps HVAC systems work faster.

Seamless tubes stop leaks and problems.

Light tubes are easy to put in place.

You can pick the size you need.

Your system works better and costs less to run.

Sometimes you need tubes that fit your special job. Huashang Steel lets you pick the size, length, and what the tube is made of. You can choose stainless steel, nickel alloys, or titanium. Each one is good for different jobs. Stainless steel does not rust, nickel alloys work with strong chemicals, and titanium stays strong in hot or cold places.

Key points for customization:

You pick the inside and outside size, wall thickness, and material.

You follow safety rules and standards.

You match the tube to your pressure and rust needs.

Tip: Custom tubes help you fix special problems in medicine, energy, and aerospace. You get the best tube for every job.

You can fix hard fluid control problems with capillary tubes from Huashang Steel. These tubes have new designs and smart ways of making them. This gives you solutions you can trust and change for your needs. Here is how these features help you:

Feature | Benefit |

|---|---|

Superelastic property | Makes systems work better and easier to use. |

Thermal shape memory | Lets you change the tube’s shape for special tasks. |

Corrosion resistance | Keeps tubes safe in hospitals and salty places. |

Weight reduction | Helps planes and cars by making them lighter. |

You will see even more uses for capillary tubes soon. Smaller and smarter tubes will help in hospitals, coolers, and cars. Huashang Steel is a leader as industries keep growing and changing.